E-mail seo@sino-purification.com

Time:2026-01-23 13:34:37 Reading volume:

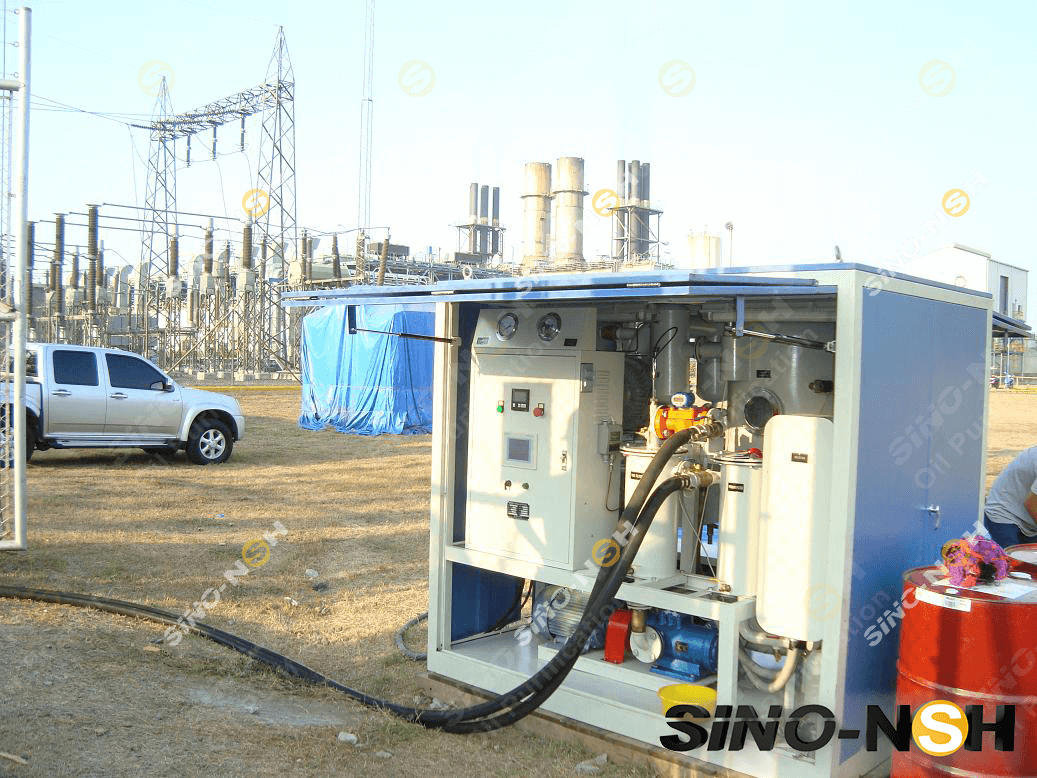

Vacuum Oil Purifier for Transformer Oil: Principles, Benefits, and Best Practices

A vacuum oil purifier for transformer oil is a specialized system designed to remove moisture, dissolved gases, and solid contaminants from insulating oil. Transformer oil is essential for electrical insulation, heat dissipation, and arc suppression in power transformers. Over time, contamination degrades oil performance and increases the risk of insulation failure and equipment damage.

Vacuum oil purification restores oil quality, improves transformer reliability, and extends both oil and equipment service life.

Contaminated transformer oil directly impacts transformer safety and efficiency:

Reduced Dielectric Strength

Moisture and dissolved gases lower breakdown voltage, increasing the risk of arcing and short circuits.

Decreased Cooling Efficiency

Water, sludge, and oxidation byproducts raise oil viscosity and limit heat transfer.

Acid Formation and Corrosion

Oxidation generates acids that corrode metal components and accelerate insulation aging.

Sludge Accumulation

Solid particles and oxidation residues restrict oil circulation and impede heat dissipation.

A vacuum oil purifier removes water, dissolved gases, and particulate contamination from transformer oil using a combination of:

Vacuum dehydration

Controlled heating

Multi-stage precision filtration

This process restores oil properties close to new-oil standards and significantly reduces maintenance and replacement costs.

Vacuum dehydration is the core technology used in transformer oil purification systems:

Pressure Reduction

A high-performance vacuum pump creates a low-pressure environment inside the treatment chamber.

Lowered Boiling Point

Under vacuum conditions, water and dissolved gases vaporize at much lower temperatures.

Controlled Heating

Moderate heating accelerates evaporation without damaging the oil.

Vacuum Extraction

Water vapor and gases are continuously removed, maintaining a stable low pressure.

Fine Filtration

Multi-stage filters remove solid contaminants, including dust, fibers, and metal debris.

Result: Dry, degassed, and clean transformer oil with restored insulating performance.

Improved Dielectric Strength

Removing moisture and gases increases breakdown voltage and reduces electrical fault risk.

Restored Thermal Performance

Clean oil regains proper viscosity, enabling efficient heat dissipation.

Reduced Acidity and Corrosion

Acidic byproducts are removed, slowing corrosion and insulation degradation.

Extended Oil and Transformer Life

Fewer oil changes and reduced downtime lower total lifecycle costs.

Environmental Benefits

Oil reuse reduces waste oil disposal and supports sustainable transformer maintenance.

Transformer oil purification systems typically include:

High-capacity vacuum pumps for efficient gas removal

Multi-stage precision filtration (usually 1–5 microns)

Online oil processing without shutting down transformers

Integrated dielectric strength testing for real-time oil quality monitoring

Dielectric Strength Testing in Transformer Oil Purification

Dielectric strength testing measures the voltage required to cause electrical breakdown in insulating oil and is a key indicator of oil condition.

Testing process:

Oil sampling

Placement in a standardized test cell

Gradual voltage increase

Recording breakdown voltage (kV)

Standards such as ASTM D877 define acceptable limits:

New transformer oil: typically ≥30 kV

In-service oil: slightly lower but within safe operating ranges

Meeting these values confirms effective vacuum oil purification.

select a purifier with appropriate capacity, vacuum level, and filtration accuracy

Schedule oil purification based on transformer load, environment, and oil condition

Follow proper safety, operational, and environmental handling procedures

Conclusion

A vacuum oil purifier for transformer oil is a proven and efficient solution for maintaining oil quality and transformer reliability. By removing moisture, gases, and solid contaminants, vacuum dehydration improves dielectric strength, enhances cooling efficiency, extends transformer life, and reduces environmental impact. With correct system selection and regular purification, operators can ensure long-term, safe, and efficient transformer operation.

Vacuum Oil Purifier for Transformer Oil: How It Works, Benefits, and Applications

Do Oil Purifiers Have Vacuum Dehydration? A Technical Overview

Insulating Oil Filtration for Power Transformers: Equipment Types and Applications

Transformer Oil Regeneration vs. Replacement: Which Is the Better Choice?