E-mail seo@sino-purification.com

Time:2025-01-22 10:47:32 Reading volume:

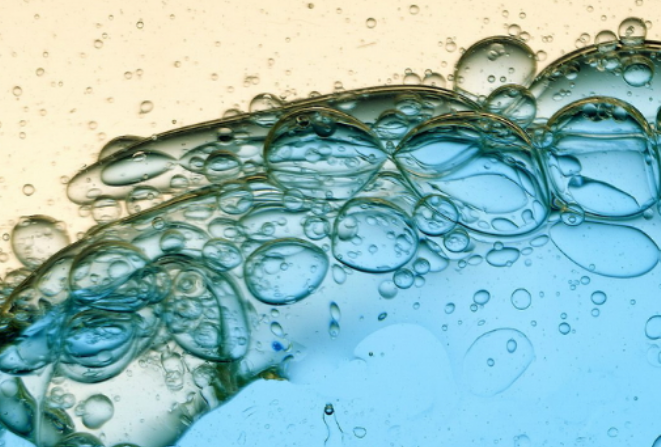

Industrial oil-water separation technologies separate oil from water in various industries such as wastewater treatment, oil spill response, and petrochemical processing. These technologies vary in their approach and are selected based on factors like the type of oil, water composition, and the specific application. Here are the main types of oil-water separation technologies:

1. Gravity Separation

- Principle: Relies on the difference in density between oil and water. Since oil is less dense than water, it floats on the surface, while the water remains at the bottom.

- Technologies:

- Oil-water separators (e.g., API separators, CPI separators, and parallel plate separators).

- Settling tanks and clarifiers: Simple systems where oil rises to the top and is skimmed off.

- Applications: Used for large volumes of water with minimal oil content, such as in refineries or oily wastewater treatment.

2. Coalescence Separation

- Principle: Involves using special media that help small oil droplets coalesce (combine) into larger droplets, which then float to the surface for easy removal.

- Technologies:

- Coalescing filters: These filters use porous media (such as a series of small tubes or plates) to trap oil droplets and allow them to combine.

- Coalescing plate separators: Similar to gravity separators but enhanced with coalescing plates that facilitate droplet aggregation.

- Applications: Common in situations where the oil is dispersed in very fine droplets (e.g., emulsified oil in water).

3. Flotation (Dissolved Air Flotation - DAF)

- Principle: Dissolved air flotation involves injecting air into the water, causing tiny bubbles to attach to oil droplets. This decreases the oil's density and causes it to rise to the surface.

- Technologies:

- DAF systems: Air is dissolved under pressure in water, and as the pressure is released, fine bubbles form and help separate oil from water.

- Induced Gas Flotation (IGF): A variant that uses gas or air bubbles to enhance the flotation process.

- Applications: Used for treating oily water in industries such as food processing, petrochemicals, and oil and gas.

4. Membrane Filtration

- Principle: Membranes filter out contaminants like oil from water by passing the water through semipermeable filters that retain larger particles.

- Technologies:

- Microfiltration and ultrafiltration: These methods use membranes to separate oil droplets and suspended solids.

- Reverse osmosis (RO): A more advanced method that can also remove smaller molecules of oil.

- Applications: Used for high-quality water treatment where fine oil droplets or emulsions need to be removed, such as in the food and beverage industry, pharmaceuticals, or wastewater recycling.

5. Chemical Treatment (Flocculation and Flotation)

- Principle: Chemicals (flocculants) are added to the water to aggregate oil droplets into larger particles, which then float to the surface or settle out.

- Technologies:

- Flocculation: Involves adding chemicals that cause the oil droplets to form larger flocs, which can then be separated by gravity or flotation.

- Chemical emulsion breaking: Chemicals are used to break emulsions and separate the oil phase from the water.

- Applications: Often used when the oil is emulsified and difficult to separate through gravity or other mechanical methods.

6. Electrocoagulation

- Principle: Uses an electric current to cause flocculation of oil particles, which can then be removed from water.

- Technologies:

- Electrocoagulation units: Apply electrical charge to the water, causing small oil droplets to agglomerate into larger particles for easier removal.

- Applications: Often used in the treatment of industrial wastewater where oil is present as fine emulsions or suspended particles.

7. Centrifugal Separation

- Principle: Uses centrifugal force to separate oil and water based on their different densities. The system spins the mixture at high speeds, causing the denser water to move outward while oil collects at the center.

- Technologies:

- Centrifuges: Machines that use centrifugal force to separate oil and water.

- Applications: Commonly used in the food industry (e.g., dairy or vegetable oil extraction) and oil and gas sectors to remove oil from produced water.

8. Absorption

- Principle: Involves using materials (often porous) that can absorb oil while allowing water to pass through.

- Technologies:

- Absorbent materials: Pads, granules, or fibers that can soak up oil from water.

- Applications: Used for small-scale or emergency oil spill cleanup operations.

9. Bioremediation

- Principle: Uses microorganisms to break down oil into less harmful substances, thus separating oil from water.

- Technologies:

- Biological treatment units: These systems encourage the growth of bacteria or other microorganisms that can degrade oil in the water.

- Applications: Typically used for treating water polluted by hydrocarbons, such as in the case of oil spills.

- Principle: Air is bubbled through the water to volatilize and strip away light hydrocarbons or oil from the water.

- Technologies:

- Air strippers: Specialized towers where air is introduced to remove volatile compounds.

The choice of oil-water separation technology depends on factors like the type of oil (free oil, emulsified, or dissolved), water composition (salinity, temperature, etc.), flow rate, and the level of separation required. Often, a combination of these technologies is employed to achieve optimal separation in industrial processes.