E-mail seo@sino-purification.com

Time:2025-10-13 13:10:32 Reading volume:

Transformer oil is the lifeblood of electrical assets, essential for insulation and cooling. When it becomes contaminated, a critical question arises: Can this used transformer oil be filtered and reused?

In most cases, used transformer oil can be professionally purified and safely returned to service. However, this is not a simple task—it's a science-driven process that must adhere to strict international standards to ensure equipment reliability and longevity.

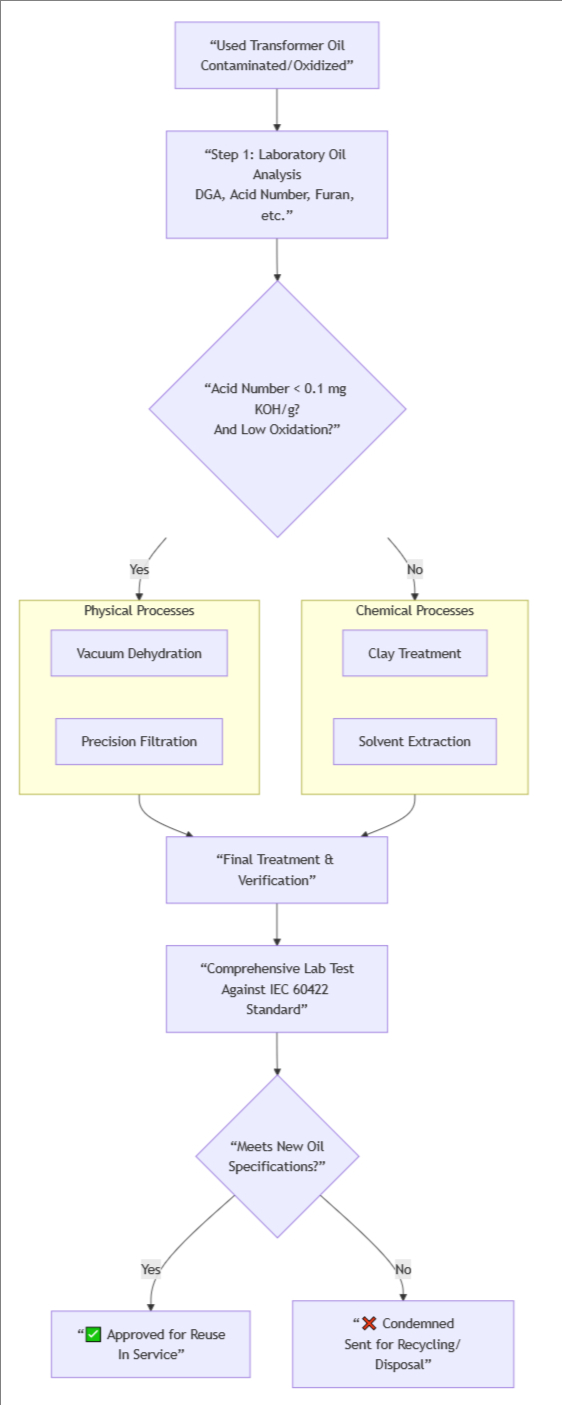

The first and most critical step is a complete laboratory analysis. You cannot treat what you have not measured. Key parameters determine the feasibility of reuse:

Dielectric Strength: Measures insulating ability. Target after treatment: > 60 kV (IEC 60156).

Acid Number (Neutralization Value): The most critical indicator of oxidation. A value below 0.1 mg KOH/g is typically required for simple purification. Values above this often require chemical regeneration.

Water Content: Target after treatment: ≤ 10 ppm (IEC 60814).

Interfacial Tension & Dissipation Factor: Indicate the presence of soluble polar contaminants and oxidation byproducts.

Dissolved Gas Analysis (DGA): Rules out underlying transformer faults that contaminated the oil.

Color & Clarity: A dark, cloudy appearance often signals advanced oxidation.

The choice of method depends entirely on the oil analysis results.

This method addresses external contaminants but does not reverse chemical aging.

Vacuum Dehydration: Heats oil to 50-65°C under a high vacuum (e.g., -0.095 MPa), effectively boiling off water and removing dissolved gases.

Precision Filtration: Utilizes filter carts with high-beta ratio (βx ≥ 200) elements to remove solid particles down to 1-5 microns, achieving cleanliness levels of ISO 4406 14/12/10 or better.

When the acid number is elevated, physical methods are insufficient.

Fuller's Earth (Clay) Treatment: Heated oil is passed through adsorptive clay, which removes acids, sludge precursors, and other polar compounds.

Solvent Extraction: Used for severe chemical contamination, such as removing PCBs or severe degradation products.

Before returning oil to service, it must be retested in a laboratory against the same stringent standards as new oil (e.g., IEC 60296). Never assume a process was successful without verification.

Consult Experts: Oil reclamation should be performed by trained personnel using certified equipment.

Proper Disposal: Oil that cannot be economically reclaimed must be handled as hazardous waste by licensed contractors.

Consider the Source: Investigate what caused the oil degradation to prevent future occurrences.

Professionally reclaiming used transformer oil is not just possible—it is a responsible practice for asset management. By following a rigorous process of Test -> Analyze -> Treat -> Verify, utilities and industries can significantly extend the life of their transformer oil, reduce operating costs, and minimize environmental impact.

Root Causes of Loss of Control in Vacuum Oil Purification Systems

How Industrial Oil Filters Remove Water and Impurities: A Comparison of Technical Principles

How to Choose the Right Industrial Oil Purifier: A Comprehensive Buyer’s Guide

How to Choose the Right Oil Purifier for Different Oil Types?

Double-Stage Vacuum Pumping: The Complete Guide to Transformer Maintenance