E-mail seo@sino-purification.com

Time:2025-01-09 10:57:35 Reading volume:

This step is critical to maintaining the environment and key to the smooth operation of many industries. It is important to delve into the complex process of removing oil from water.

This comprehensive guide will take you through the various methods and technologies involved in this critical environmental service, and provide insights into how to address this complex challenge in an efficient and precise manner.

Overview of the Basics of Oil-Water Separation

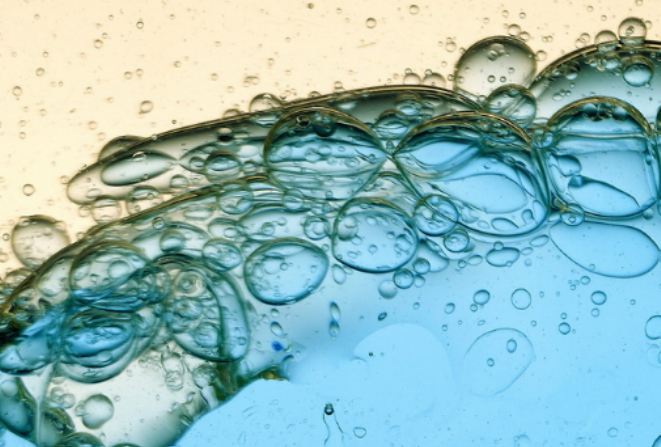

Oil-water separation aims to extract oil and other hydrocarbons from water. This process is essential in many industries, especially in the oil and gas sector, where water is often produced as a byproduct.

Due to the different chemical and physical properties of oil and water, separation is difficult. Oil has a low density and tends to float on the surface of water, forming a film that is difficult to degrade.

Overview of Oil-Water Separation Strategies

Gravity Sedimentation

Gravity sedimentation takes advantage of the fact that oil naturally floats on the surface of water due to its low density. In this method, the oil-water mixture is allowed to settle and over time, the oil layer gradually rises to the surface for subsequent removal. This method is simple and cost-effective and is suitable for thick oil layers with a clear boundary with the water layer.

This method is particularly useful in industries where oil pollution is widespread. However, it may be less effective when the oil and water are more evenly mixed (such as in an emulsion), and other strategies may be more appropriate.

Centrifugal separation technology

Centrifugal separation technology uses the centrifugal force generated by rapid rotation to separate materials of different densities. In this process, the centrifuge spins the oil and water mixture at high speed, and the denser water moves to the outside, while the less dense oil moves to the center, making it easier to collect the oil and water separately.

This technology is efficient and fast, making it ideal for industrial applications that require rapid processing. However, it can be relatively expensive due to the energy required to purchase and operate the equipment.

Coalescing separation method

The coalescing separation method simplifies the oil and water separation process by combining tiny oil droplets into larger oil droplets. Tiny oil droplets in the water merge into larger oil droplets and float to the surface faster. This method is effective when treating emulsions where the oil and water are evenly mixed.

This process requires the use of special materials or chemical reagents to promote the coalescence of oil droplets. This method has value in a variety of industrial settings, especially when traditional methods such as gravity settling have failed.

Filtration Technology Explanation

Filtration technology involves passing the oil-water mixture through a filter that allows water to pass while intercepting the oil droplets. This is a simple method that is often used when the oil droplets are small and dispersed in the water. The effectiveness of the filtration depends on the type of filter and the characteristics of the oil-water mixture.

Filtration systems vary in complexity, ranging from simple paper filters to advanced industrial-grade systems. This method is particularly useful when other separation methods are not suitable.

Flotation Separation Technology

Flotation separation technology introduces tiny air bubbles into the oil-water mixture. The bubbles attach to the oil droplets and float them to the surface of the water for easy skimming. This method is very effective in separating tiny oil droplets that are difficult to remove by other methods.

Flotation separation technology is commonly used in wastewater treatment and other industrial processes. Its versatility in adapting to different types of oil-water mixtures makes it popular in many industries.

Biodegradation Methods

Biodegradation methods use microorganisms to break down and remove oil from water. In this method, bacteria or other microorganisms are introduced into the oil-water mixture and feed on the oil, effectively removing the oil. This method is environmentally friendly and efficient, especially for treating large bodies of water.

However, biodegradation is time-consuming compared to physical separation methods. It is best suited for situations where time is not a primary consideration and environmentally sustainable solutions are the priority.

Thermal separation methods

Thermal separation methods use heat to separate oil from water. Distillation is one of the common methods, which heats the mixture until the water evaporates and then condenses the water vapor back into a liquid state, leaving the oil. This method is effective for separating oil and water mixtures with significantly differ