E-mail seo@sino-purification.com

Time:2025-05-29 14:56:31 Reading volume:

Turbine oil (steam turbine oil) dehydration is a key process in the power, petrochemical and other industries, which directly affects the safe operation of the unit. The following is a detailed explanation of the professional-grade turbine oil dehydration process:

Based on the oil-water boiling point difference and surface tension characteristics, the water vaporization temperature is reduced under a vacuum environment (40-60℃ can boil), achieving gentle dehydration without damaging the oil.

1. Pretreatment stage

- Coarse filtration: 20μm stainless steel filter to remove particulate matter

- Heating system: Indirect heating of thermal oil to 50-55℃ (avoid local overheating)

- Free water separation: Gravity separation in a conical sedimentation tank (remove more than 90% of free water)

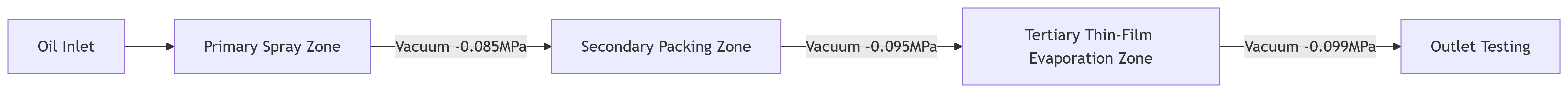

2.Three-stage treatment of the vacuum dehydration tower

- Primary spray area: Rotating nozzle forms an oil film to remove large water droplets

- Secondary packing area: Stainless steel θ ring packing increases the contact area

- Third-stage thin film evaporation: Scraping film system forces film formation to remove dissolved water

3. Post-treatment system

- Precision filtration: 3μm glass fiber filter element (NAS 1638 level 6)

- Online monitoring: Capacitive moisture sensor (±5ppm accuracy)

| Parameters | Control range | Monitoring means |

|---------------|-----------------------|------------------------|

| Working vacuum degree | -0.096~-0.099MPa | Capacitive vacuum gauge |

| Oil temperature | 50±2℃ (mineral oil) | PT100 temperature sensor |

| Circulation ratio | 1:3 (processing volume: oil tank volume) | Flow meter linkage control |

| Residence time | ≥15 minutes/cycle | PLC timing control |

1. Vacuum system

- Recommended Roots pump + rotary vane pump combination

- Ultimate vacuum must be below 5Pa

- Equipped with a condenser to recover water vapor

2. Degassing tower design

- Material: 316L stainless steel

- Packing height ≥800mm

- Effective volume ratio ≥1:5

3. Safety configuration

- Explosion-proof heater (Ex dⅡBT4)

- Vacuum circuit breaker (<-0.1MPa automatic shutdown)

- Oxygen content monitoring (< 8% VOL)

1. Moisture content

- New oil standard: ≤30ppm (GB/T 7600)

- Operating oil: ≤50ppm (DL/T 1461)

2. Gas content

- Air release value ≤3 minutes (ISO 9120)

- Foam characteristics ≤150/0ml (ASTM D892)

3. Cleanliness

- Number of particles ≤1000/mL (>6μm)

1. Emulsified oil treatment

- Add 0.01% demulsifier (such as T1001) first

- Control the oil temperature at 45℃ and stir at low speed

- Vacuum treatment after standing for 4 hours

2. Anti-oil dehydration

- A fluororubber sealing system is required

- Temperature limit ≤55℃

- Ordinary molecular sieve is prohibited

- Treatment cost: ¥0.8-1.2 yuan/liter (including energy consumption and consumables)

- Save 60% of the cost compared to oil replacement

- Equipment payback period:<1 year (based on 200 tons of annual processing)

This process can make turbine oil:

- Water removal rate > 99.9%

- Oil life extended by 3 times

- Unit vibration value reduced by 30%

Note: For units above 300MW, it is recommended to configure an online vacuum dehydration device to achieve real-time maintenance. The treated oil needs to be tested for breakdown voltage (≥50kV/2.5mm) before it can be reused.