E-mail seo@sino-purification.com

Time:2025-08-07 13:29:07 Reading volume:

The mesh size (or filtration accuracy) of filter paper used in oil filters should be selected based on the oil type, contamination level, and equipment requirements. Common ranges are as follows:

| Mesh Size (Mesh) | Corresponding Filtration Accuracy (μm) | Applicable Scenarios |

|-------------------------|---------------------------------------------|-----------------------------------------------------------------------|

| 60-100 mesh | 150-250 μm | Coarse filtration (e.g., large particle removal, primary filtration) |

| 150-200 mesh | 75-100 μm | General industrial oils (e.g., lubricating oil, hydraulic oil) |

| 300-400 mesh | 40-50 μm | Fine filtration (e.g., transformer oil, turbine oil) |

| 500 mesh and above | ≤20 μm | High-purity oils (e.g., insulating oil, pharmaceutical-grade oil) |

1. Transformer Oil Filters

- Recommended: 300-400 mesh (40-50 μm) filter paper, or higher-precision filter paper (e.g., 5-10 μm glass fiber filter paper).

- Standard: Must meet the requirements of DL/T 1095, "Guidelines for Transformer Oil Maintenance and Management" (impurity particles ≤ 5 μm).

2. Lubricating Oil/Hydraulic Oil Filter

- Recommended: 150-200 mesh (75-100 μm) for coarse filtration, with a 10-20 μm fine filter element added.

3. Fuel Oil Filter

- Recommended: 100-150 mesh (100-150 μm) for removing moisture and particles. Some filter media may require 3-5 μm fine filtration.

Notes

1. Relationship between Mesh Number and Micrometers:

- Mesh number refers to the number of sieve openings per square inch. Higher mesh numbers indicate higher precision. However, please note the conversion differences between different standards (e.g., ISO/ASME).

- For example: 200 mesh ≈ 74 μm (US standard), while the same mesh size may correspond to 75 μm in China.

2. Multi-layer composite filtration:

- Modern oil filters often use a combination of "coarse filtration + fine filtration" (e.g., first using a 100 mesh filter to remove impurities, then using a 5 μm filter element to remove fine particles).

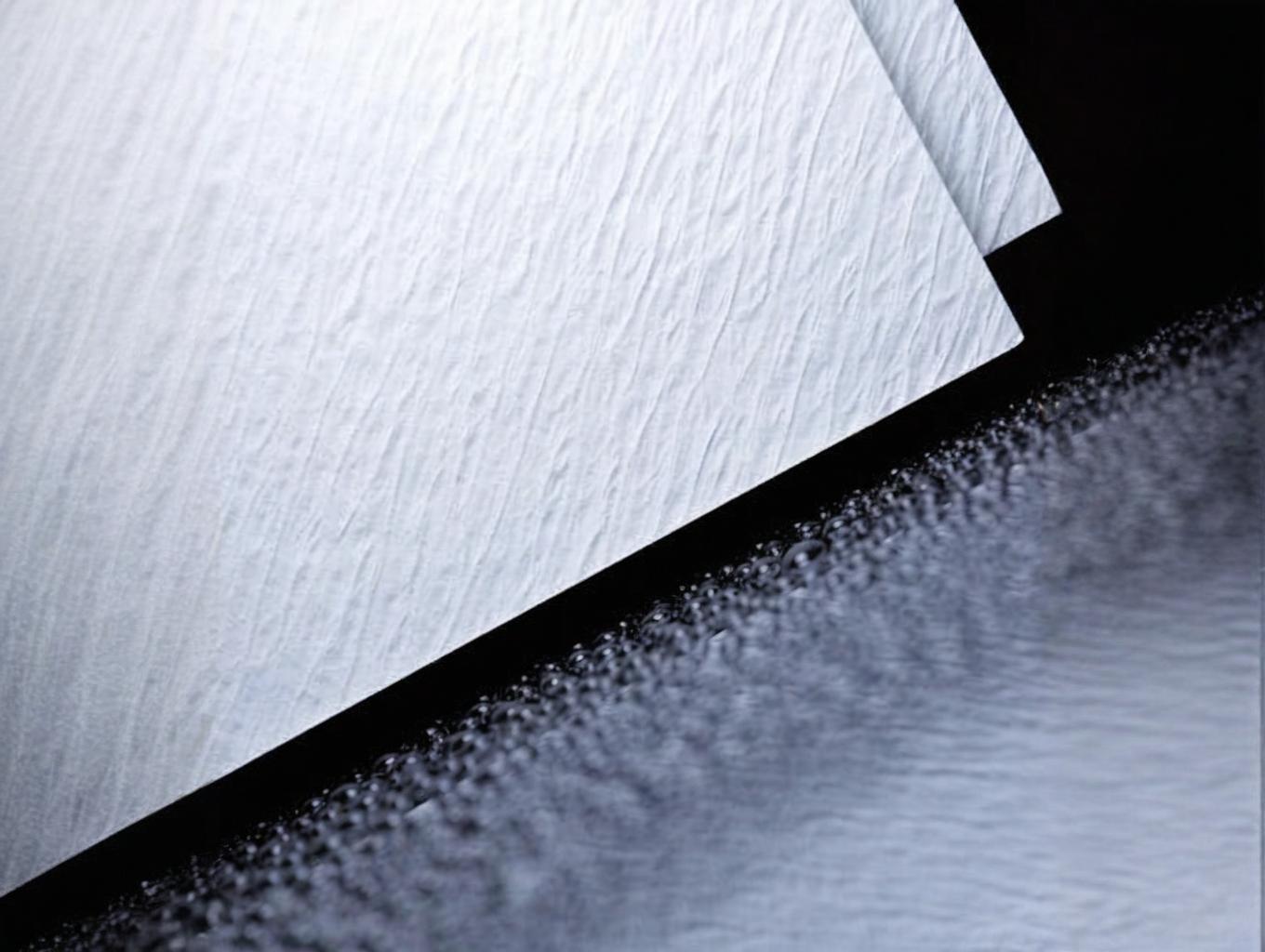

3. Filter paper material:

- Ordinary filter paper: Suitable for general mineral oils (temperature resistant 80-120°C).

- Glass fiber filter paper: High-temperature resistant (above 200°C), high-precision (up to 1 μm), suitable for synthetic oils or high-temperature environments.

4. Replacement criteria:

- replace the filter paper when the surface becomes noticeably black, the differential pressure exceeds 0.3 MPa, or the filtration rate decreases.

- Refer to the oil test report: such as particle contamination (ISO 4406), water content (ASTM D6304), and other data.

- Equipment Requirements: Check the filter fineness indicated in the oil filter manual (e.g., "10 μm filter element required").

- Consult the supplier: Provide an oil sample and operating conditions (temperature, flow rate) for customized recommendations.

Note: The mesh size is for reference only. The actual filter fineness (μm) should be used as the reference. The nominal mesh size may vary between filter paper brands.