E-mail seo@sino-purification.com

Time:2025-10-31 13:17:13 Reading volume:

Centrifugal Oil Filter Leaking: Causes, Troubleshooting, and Solutions

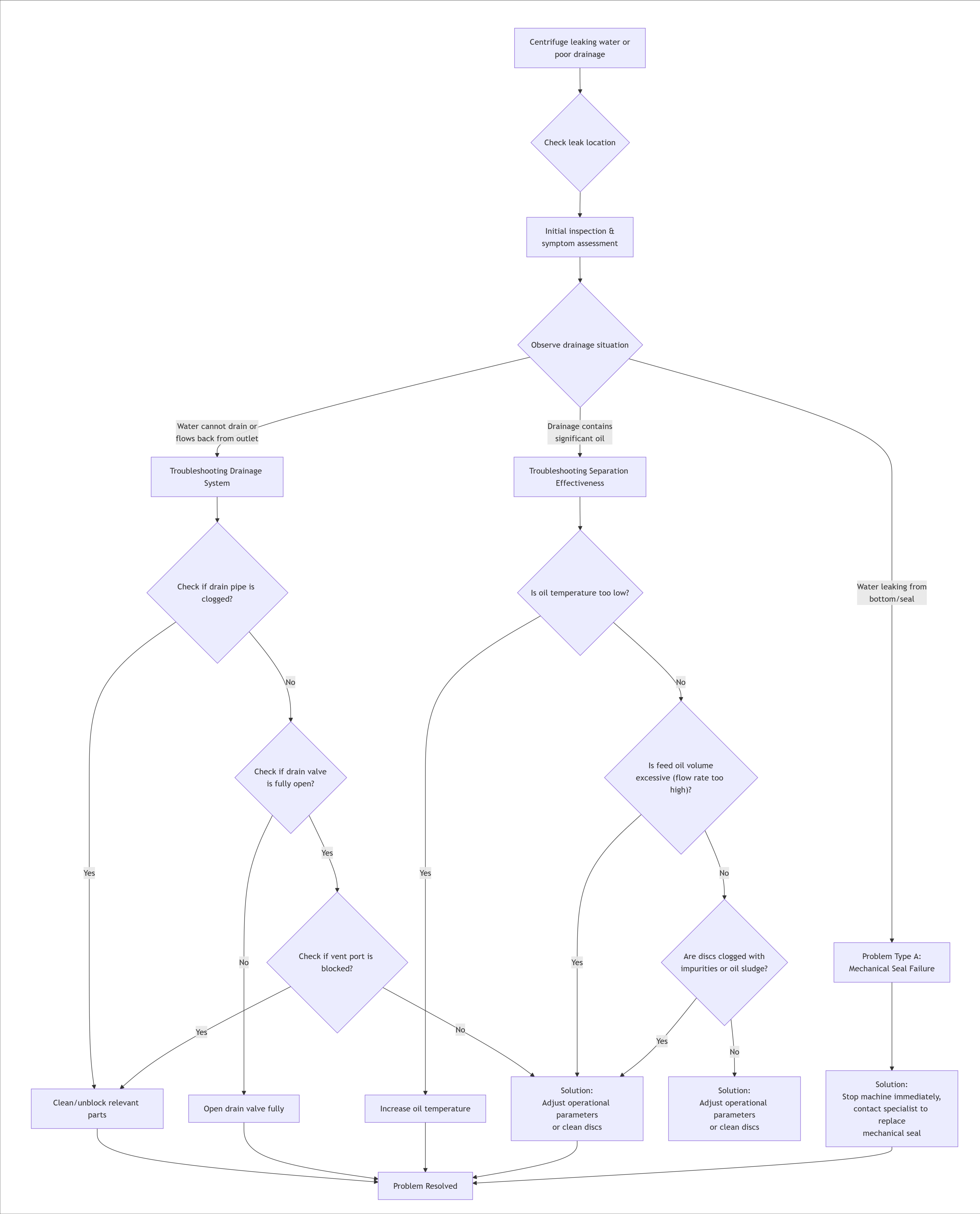

A leaking centrifugal oil filter is a critical issue that requires immediate attention. Leakage generally occurs in two forms:

Water leaking externally from the machine.

Poor separation causes water to remain in the oil.

Below is a detailed guide to quickly diagnose and fix the problem.

Problem Type A: Mechanical Seal Failure (Most Serious)

Symptoms:

Continuous water leakage from the bottom seal, main shaft, or end cover.

Main Causes:

Aging or worn seal rings: The mechanical seal or O-ring loses elasticity after long use.

Incorrect installation: Improper assembly damages the seal surface.

Main shaft wear or scratches: Hard particles cause friction and damage the sealing surface.

Solution:

Immediately stop the machine and close the oil inlet valve.

Do not repair on-site — contact a qualified technician.

replace the mechanical seal and O-rings; if the spindle is worn, it must be repaired or replaced.

Problem Type B: Drainage System Blockage or Malfunction

Symptoms:

Water does not drain or drains very slowly.

Common Causes:

Blocked drain pipe: Sludge or impurities clog the line.

Drain valve malfunction: The ball or solenoid valve is stuck or not energized.

Vent hole blockage: Air pressure prevents normal drainage.

Solutions:

Clean the drain pipe thoroughly with water or tools.

Check and open the valve; if solenoid-type, ensure proper power supply.

Unblock the vent hole near the drain valve using a fine needle or wire.

Problem Type C: Poor Separation (Oil-Water Mixing)

Symptoms:

Water discharge contains oil, or outlet oil has high water content.

Low oil temperature: High viscosity reduces separation efficiency.

→ Preheat oil to 40–60°C before operation.

Excessive flow rate: Oil passes too quickly for proper separation.

→ Reduce inlet flow to within rated capacity.

Disc blockage: Sludge fills disc gaps and blocks channels.

→ Stop operation, disassemble the drum, and clean all discs manually.

Routine disc cleaning is vital to maintain efficient separation.

Always cut power before maintenance or cleaning.

After each operation: Remove sludge and rinse the drum.

Regularly clean the internal discs and bowl based on usage frequency.

Operate within rated limits: Avoid exceeding maximum throughput.

Preheat viscous oils before startup.

Inspect drain valves and piping for normal operation before each use.

Summary

When a centrifugal oil filter leaks, first identify the source: seal failure, drainage issue, or poor separation.

Mechanical seal damage is the most severe case and requires professional service.

Most leaks result from blockages, valve faults, or poor maintenance, which can be prevented through routine cleaning and correct operation.

Proper inspection, regular cleaning, and temperature control are key to ensuring long-term stability and leak-free performance.

Root Causes of Loss of Control in Vacuum Oil Purification Systems

How Industrial Oil Filters Remove Water and Impurities: A Comparison of Technical Principles

How to Choose the Right Industrial Oil Purifier: A Comprehensive Buyer’s Guide

How to Choose the Right Oil Purifier for Different Oil Types?

Double-Stage Vacuum Pumping: The Complete Guide to Transformer Maintenance